🎁 Introduction: The Rise of Premium Packaging

In high-end retail, packaging is more than protection—it’s a statement of brand value. A well-engineered rigid box communicates exclusivity, quality, and precision. Yet behind that luxury feel lies careful structural design aimed at reducing material waste and optimizing logistics.

Whether for cosmetics, electronics, or jewelry, partnering with a professional Rigid Boxes Manufacturer ensures your packaging not only looks premium but performs efficiently from production to delivery.

🧱 What Makes Rigid Boxes Different?

Unlike folding cartons, rigid boxes are pre-assembled using dense paperboard wrapped with printed paper or fabric. They maintain shape under pressure, making them ideal for luxury goods.

🔹 Core Components

-

Greyboard / Chipboard: Provides stiffness and dimensional stability.

-

Wrap Paper: Adds visual appeal through textures, coatings, or prints.

-

Liner Paper: Protects the product and supports the structure.

The engineering process balances aesthetic perfection with functionality, ensuring each fold and corner reflects precision craftsmanship.

⚙️ Engineering Principles That Define Quality

The quality of a rigid box depends on how efficiently it’s designed and assembled. Here’s what top manufacturers focus on:

🔧 1. Board Thickness Optimization

Using the correct caliper prevents over-engineering. For most retail boxes, 1.2–2.5 mm board is sufficient for stability without extra weight.

📐 2. Tight Tolerances

Corners, edges, and cover wraps must align within ±0.5 mm tolerance for flawless symmetry. Precision dies and jigs are crucial here.

🪶 3. Smart Material Layout

Die-cut layouts are optimized to minimize paper waste. Efficient nesting patterns can save up to 10–15% of material cost in mass production.

💨 4. Automated Assembly

Modern factories use semi-automatic or robotic wrapping machines to enhance consistency and reduce manual glue waste.

🌿 Sustainability: Reducing Waste Without Compromising Luxury

Luxury doesn’t have to mean excess. New-generation rigid packaging uses eco-conscious materials such as:

-

Recycled greyboard (up to 90% post-consumer fiber)

-

Water-based adhesives and soy-based inks

-

Textured kraft or cotton papers for natural tactile appeal

These sustainable materials offer the same elegance as conventional ones but with a smaller carbon footprint.

Your Custom Cardboard Boxes Manufacturer can integrate recycled cores and FSC-certified wraps into your rigid packaging line—balancing style, function, and sustainability.

🎨 Design Strategies for Visual and Structural Balance

✅ Use contrasting finishes: Combine matte and gloss to highlight premium features.

✅ Reduce component layers: Eliminate redundant paper wraps to cut waste.

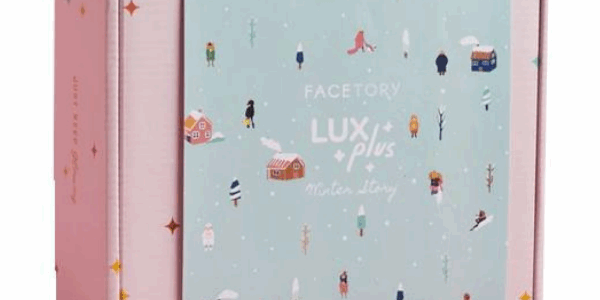

✅ Experiment with structures: Book-style, drawer, or magnetic closure formats each serve different unboxing flows.

✅ Add internal trays or inserts: Protect delicate items while enhancing perceived value.

By applying these techniques, brands achieve luxury appeal with lower environmental impact—a vital advantage in modern retail.

💡 Cost Efficiency Through Engineering

Rigid boxes can be expensive if not engineered properly. Key factors influencing cost include:

-

Manual labor time: Minimized with semi-automated wrapping.

-

Material utilization: Improved through digital die-cut optimization.

-

Shipping volume: Foldable or collapsible rigid boxes save up to 60% in freight cost.

Prototyping and compression testing help refine these parameters before full-scale production, ensuring long-term savings.

🧭 Case Example

A high-end watch brand reduced material waste by 18% after redesigning its magnetic rigid box structure. By switching to recycled 1.5 mm board and automated glue application, they achieved consistent quality while cutting assembly time by 30%.

The lesson: luxury packaging can evolve without sacrificing quality or brand perception.

🧾 Conclusion: Engineering the Future of Luxury Packaging

Rigid boxes represent the intersection of design, engineering, and sustainability. With smart structural planning and material innovation, brands can maintain luxury aesthetics while reducing cost and waste.

To achieve precision at scale, collaborate with a reliable Rigid Boxes Manufacturer and coordinate your sustainable packaging strategy with a Custom Cardboard Boxes Manufacturer. Together, these experts can help your brand deliver elegance with purpose.